In today’s construction and manufacturing industries, innovative materials are swiftly replacing traditional ones. One gaining attention is FRP. But what exactly is FRP? And why are a growing number of industries, particularly in India, opting for it over steel, wood, or concrete? This article explains what FRP is, its benefits, and why it’s rapidly becoming the preferred choice for many businesses, including FRP walkway fabricators and Solar EPC company in India.

Understanding FRP Material

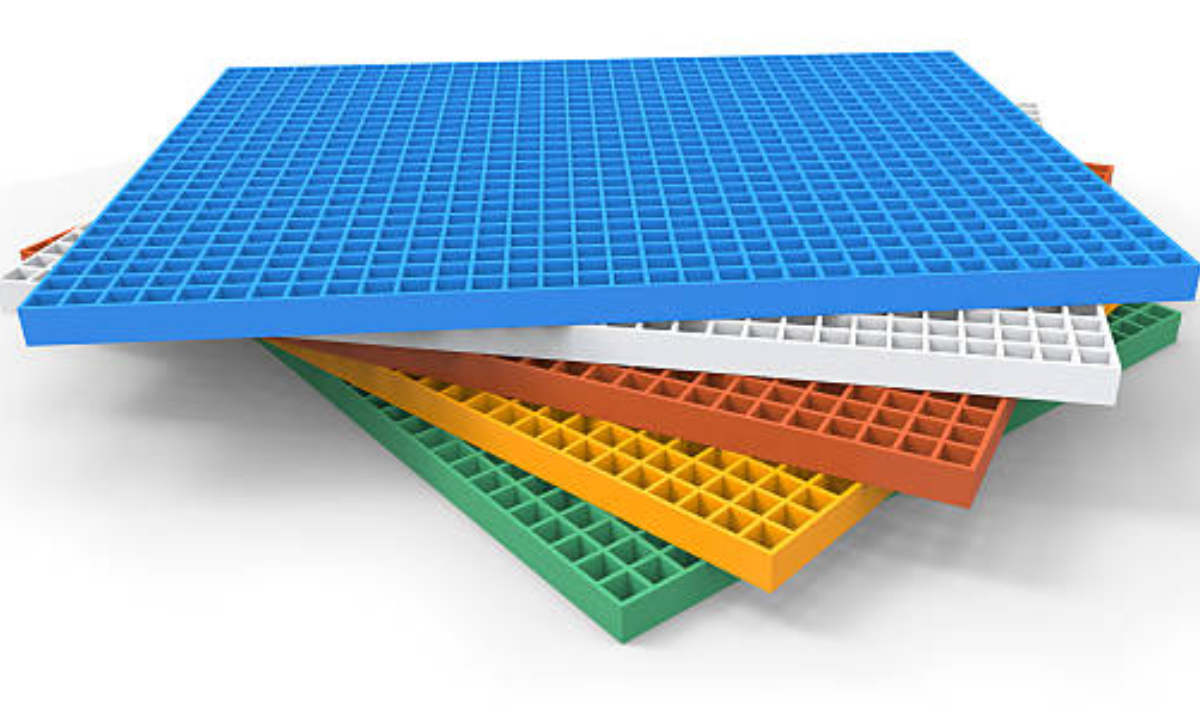

FRP stands for Fiber Reinforced Plastic. It is a polymer reinforced with fibers, produced by embedding a polymer matrix (usually plastic) with a bundle of reinforcing fibers (typically glass, carbon, or aramid). The result is a high-performance, lightweight, and durable material with diverse applications. When people refer to FRP material, they mean this advanced composite of plastic and fibers.

How Is FRP Made?

FRP is composed of robust fibers embedded in a plastic resin, then shaped as required. The fibers supply strength and stiffness; the plastic provides form and shields the structure. The mixture can be molded into sheets, rods, pipes, or intricate grating for walkways.

Why are FRP materials superseding conventional materials?

Corrosion Resistance – Final Frontier

Among the most outstanding benefits of a FRP material is the Corrosion Resistance. In contrast to the tendency or propensity of steel to rust or wood to rot, the FRP material is corrosion-resistant to chemicals, water, and even salt. This is what makes it a favorite among industries whose materials wear out easily. As an example, a FRP walkway manufacturer can now offer products suitable for harsh chemical plants or coastal environments where rust and rot would be an issue.

Moreover, the corrosion-resistant nature of FRP material is also attractive for implementation in any infrastructure project, where low maintenance and maximum life are required. This is a paradigm shift in the treatment of water, factories, and even bridges.

Lightweight and Strong

RP material is significantly lighter than steel or concrete; however, it can be equally strong. This eases transportation, handling, and installation and reduces its cost. As an example, two workers can heft FRP grating in walkway applications without the use of cranes or heavy equipment. However, it can securely handle the loads as other conventional materials do.

Design and Flexibility

Conventional materials have their limits: they only bend or deform to a certain extent before breaking. For instance, a FRP walkway manufacturer can tailor walkways to fit unique factory layouts or style requirements.

Areas Where FRP Is Winning

Industrial Settings

Factories and processing plants are some of the first places to adopt FRP material. Chemicals, water, and temperature variations can destroy steel or wood in a short time. But FRP withstands those conditions for years.

Unsurprisingly, FRP manufacturers in Bangalore have witnessed increased demand by domestic and overseas companies that require durable and corrosion-proof structures.

Public Infrastructure

FRP is widely applicable in the public works sector as well, whether in the span of pedestrian bridges, in the cover of urban drain pipes, and in several more applications. Because of its bright colors and its non-slip surface, it will avoid the occurrence of accidents, and since it is durable through its long-lasting durability, it will require less maintenance, and replacement will be costly. That is why numerous municipalities today resort to FRP suppliers in Bangalore to upgrade their infrastructure.

Sector Renewable Energy

The solar sector is also going green with FRP being used by a solar EPC company in India as mounting structures, cable trays, and safety walkways. Conventional steel components are highly susceptible to rusting, particularly when the components are used on rooftops where they are exposed to the external elements. The RP is not afflicted by UV emission or rain, so it is a resistant and light moderate that fits in the rising and fast-growing solar realm.

Comparison of FRP with Various Materials

| Feature | Steel | Wood | FRP Material |

|---|---|---|---|

| Weight | Heavy | Medium/Light | Very Light |

| Strength | High | Low/Medium | High |

| Corrosion Resistance | Low | Low | High |

| Maintenance | High | High | Low |

| Shape Flexibility | Low | Medium | High |

| Longevity | Medium | Low | High |

Why Businesses are Switching

Lower Lifetime Costs

FRP may not be cheaper than steel or wood initially, but due to its low maintenance requirements and longevity, it costs less in the long term. Less repair and replacements is required, which is good news to any organization keeping an eye on its profit margin.

Safety and compliance

The materials needed in many industries must be non-conductive or fire-retardant. The FRP material can be designed to provide both, thereby qualifying to be used in contemporary regulations and safety standards. For example, a Solar EPC company in India benefits from FRP’s non-conductivity around solar arrays.

Local Expertise

Local FRP manufacturers in Bangalore and other technological hotspots have increased the range of their activities with the rise in demand. They offer tailor-made services to projects as diverse as chemical plants and public parks, and they ensure that the quality and on-time delivery are achieved.

Challenges/Limitations

Nothing is an ideal material. Although FRP has a lot of positive aspects, it also has its hassles:

- Cost: Start-up expense may be larger, but this is recovered through the life with less maintenance.

- Solar or UV Exposure: Some FRP can deteriorate because of exposure to naked sunlight.

- Low awareness: Not all the decision-makers are conversant with the material, although this is changing as the success story spreads.

Future of FRP Material

It is predicted that industries will continue to use FRP rapidly. With the augmenting environmental restrictions and the movement to being sustainable, materials that have longer life expectancy and less maintenance are needed. Advances in the process of manufacturing, including breakthroughs by top FRP walkway manufacturers and FRP manufacturers in Bangalore, are also making FRP reach more industries.

Additionally, as India’s infrastructure and renewable energy sectors grow, especially with the rise of every Solar EPC company in India, FRP’s unique qualities will keep it at the forefront, especially where corrosion resistance is crucial.

Conclusion

FRP material is quickly becoming the future material. The incredibly lightweight, yet strong, corrosion-resistant, and flexible forms gave it the ability to find uses in a wide variety of industries, including those that produce chemicals and those that generate solar power. Since more organizations are understanding the utility it has, in addition to more FRP manufacturers in Bangalore and other parts of the country, FRP is likely to dominate most of the traditional materials in the future.

Do you work in construction, manufacturing, renewable energy, or public works? Then think FRP the next time you have a project. Not only will the quality be durable, but also be beneficial towards a low-maintenance and sustainable future.

Key Takeaways

- Fiber Reinforced Plastic, or F-R-P, is a combination of plastic and fibers, which are highly resistant to corrosion and their strength.

- FRP is being used more in rural markets than metal or wood, as it has a longer lifespan and can be effectively used in various industries.

- It’s especially valuable for FRP walkway manufacturers and Solar EPC company in Indian sectors.

- With reliable FRP manufacturers in Bangalore, supply and customization have never been easier.

- FRP is in a good position because companies are interested in less costly and time-consuming materials.

Shobha Globs is a leading-edge service provider and Solar EPC company in India, guaranteeing quality work in EPC by providing quality installations that are more efficient, environmentally conscious. Contact us today to learn how we can power your next solar venture!