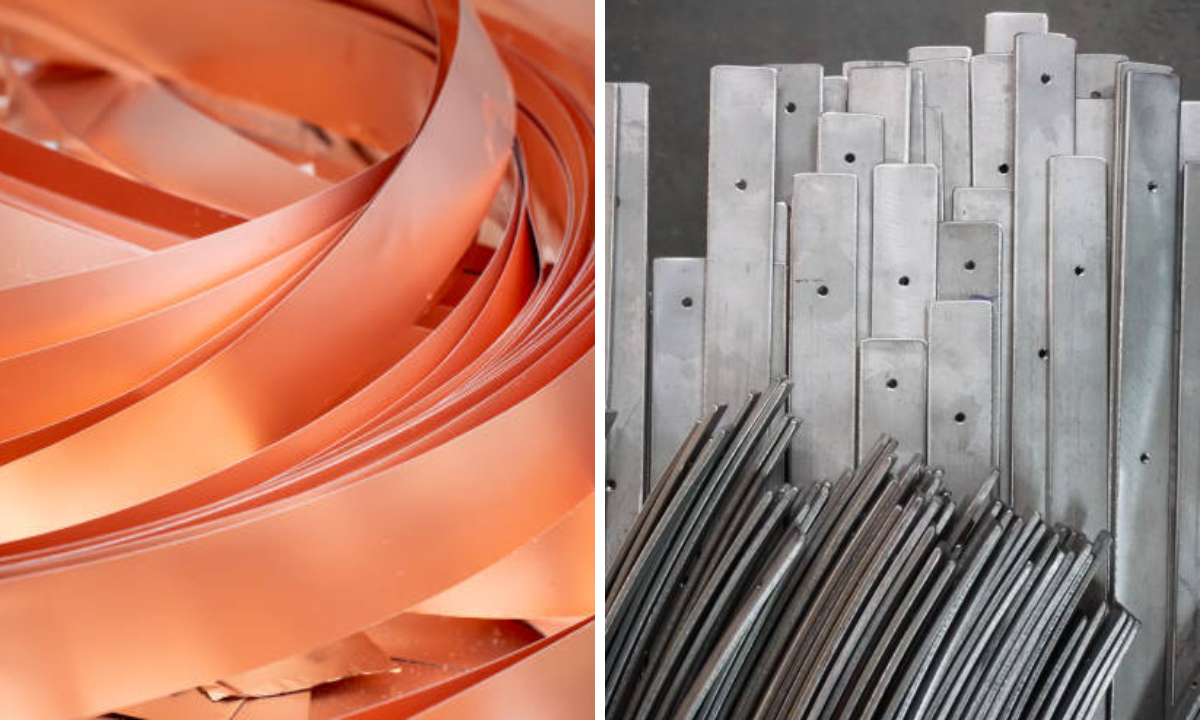

When it comes to safe and reliable electrical systems, earthing strips play a vital role. Whether it is a residential project, a commercial setup, or a large-scale renewable energy project handled by a Solar EPC Company in India, proper earthing ensures safety, durability, and stable performance. Among the most commonly used options are copper earthing strips and GI earthing strips (Galvanized Iron). Both have their advantages, and choosing the right one depends on your specific needs, budget, and application.

In this blog, we will explain the differences between copper and GI strips, their benefits, and which one may be the better choice for your requirements.

What is an Earthing Strip?

An earthing strip is a flat metal conductor used to create a safe path for fault currents to flow into the ground. This helps protect people and electrical equipment from potential hazards caused by voltage fluctuations, lightning strikes, or short circuits.

Electrical consultants, contractors, and earthing strip manufacturers in India offer strips in various materials, thicknesses, and sizes to meet diverse requirements. Among these, copper and GI strips are the most preferred options.

What is Galvanized Earthing Strip?

Before we compare, let’s understand what is galvanized earthing strip.

A galvanized earthing strip is made from mild steel (MS) that is coated with zinc to protect it from corrosion. This zinc coating makes the strip more durable compared to plain steel, especially when exposed to moisture and soil conditions.

GI earthing strips are widely used because they are affordable, strong, and provide reasonable corrosion resistance. They are often recommended for projects where cost-effectiveness is a priority, and the soil is not too corrosive.

Copper Earthing Strip

A copper earthing strip is made of pure copper or tinned copper. Copper has the highest electrical conductivity of all non-precious metals, which means it can carry large fault currents with minimal energy loss.

Advantages of copper include:

- Superior conductivity – ensures efficient current flow

- Excellent corrosion resistance – ideal for harsh environments

- Long life – copper strips can last decades with minimal maintenance

- Preferred choice for solar power plants, data centers, hospitals, airports, and industries

Though copper is more expensive than GI, many experts, including earthing strip manufacturers, recommend it for critical applications where safety cannot be compromised.

Applications of Copper and GI Earthing Strips

1. Residential Projects

For homes, apartments, and small offices, GI earthing strips are commonly used. They are strong, reliable, and much more cost-effective. Since residential load requirements are moderate, GI strips work well in most cases.

2. Industrial Projects

Factories, refineries, and chemical plants need a high level of safety. For these, copper earthing strips are often recommended because they can handle higher fault currents and resist corrosion, especially in chemical-rich environments.

3. Data Centers & Hospitals

These are critical infrastructures where downtime or equipment failure can result in huge losses. Here, copper earthing strips are the clear choice due to their efficiency and reliability.

4. Solar Power Plants

A Solar EPC company in India would generally suggest copper earthing strips. Solar panels, inverters, and batteries are expensive, and reliable earthing ensures their long-term protection against surges and lightning.

5. Commercial Complexes

Shopping malls, IT parks, and office complexes can use either copper or GI, depending on the budget. Many choose copper for critical sections (like server rooms) and GI for general areas.

Copper vs. GI Earthing Strips: Key Differences

Here’s a simple comparison between copper earthing strips and GI earthing strips:

| Feature | Copper Earthing Strip | GI Earthing Strip |

|---|---|---|

| Conductivity | Excellent (highest electrical conductivity) | Moderate (lower than copper) |

| Corrosion Resistance | Very high | Medium (zinc coating provides some protection) |

| Durability | Long-lasting, even in harsh environments | Good, but shorter lifespan compared to copper |

| Cost | Expensive | Affordable |

| Applications | High-load industries, data centers, hospitals, solar plants | Residential buildings, small industries, cost-sensitive projects |

Role of Earthing Strips in Solar Projects

With the growing adoption of solar energy, the demand for quality earthing solutions has also increased. A reliable Solar EPC Company in India will always emphasize proper earthing systems to protect solar panels, inverters, and batteries from damage.

Here, copper earthing strips are generally preferred due to their ability to handle large fault currents and resist corrosion, ensuring the solar setup works smoothly for decades.

Why Choose a Reliable Earthing Strip Manufacturer in India?

When it comes to safety, the quality of the material matters as much as the installation. Partnering with an experienced earthing strip manufacturer in India ensures:

- High-quality raw materials

- Proper galvanization or copper purity

- Custom sizes and thicknesses for specific needs

- Compliance with industry standards

A trusted manufacturer not only provides durable strips but also guides you in selecting the right type for your project.

Final Thoughts

Both copper earthing strips and GI earthing strips serve the purpose of grounding, but the best choice depends on your project’s requirements. If you are looking for affordability and moderate performance, GI strips are a good option. However, if your priority is long-term reliability, safety, and superior conductivity, copper strips are the better choice.

For residential projects, GI strips may work well, but for large-scale projects like solar power plants, data centers, and industrial setups, copper strips are worth the investment.

When in doubt, consult an experienced electrical contractor or a reputed earthing strip manufacturer in India who can assess your project and guide you. Remember, earthing is not just a technical requirement — it’s an investment in safety and peace of mind.