When setting up any electrical system, safety is the priority. One key component that ensures safety is an earthing strip. But many contractors, industries, and builders often ask, “Which Earthing Strip Manufacturer in India should I choose?”

In this detailed blog by Shobha Globs, a leading Earthing Strip Manufacturer in India, we will cover:

- What are earthing strips?

- Types of earthing strips

- Advantages and uses

- How to choose the best manufacturer

- Market trends and FAQs

What is an Earthing Strip?

An earthing strip is a flat metal strip used to connect electrical systems to the ground safely. It ensures that any leakage or fault current flows directly into the earth, protecting people, equipment, and structures from electric shocks or fire hazards.

Why are Earthing Strips Important?

- Protect against electrical shocks

- Prevent damage to electrical equipment

- Ensure safety in homes, offices, industries, and plants

- Maintain system stability during lightning or faults

Types of Earthing Strips Available in India

1. GI Earthing Strips

GI (Galvanized Iron) strips are the most common choice in India.

- Made by coating iron strips with zinc to prevent rust

- Cost-effective with good conductivity

- Widely used in residential, commercial, and industrial projects

- Available in sizes like 25×3 mm, 25×6 mm, 50×6 mm, and customized sizes

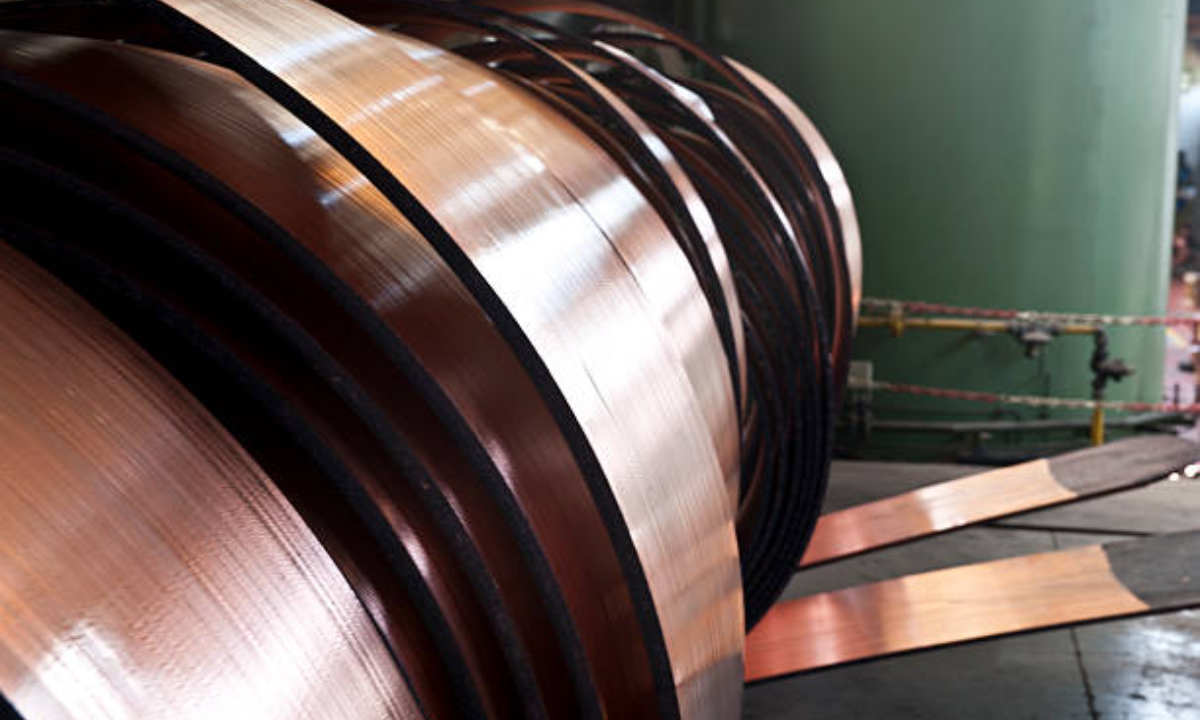

2. Copper Earthing Strips

Copper strips are known for their excellent electrical conductivity.

- High corrosion resistance

- Used in industries needing higher safety, like oil refineries, chemical plants, and power plants

- More expensive than GI strips, but they provide better performance

3. Aluminium Earthing Strips

Aluminium strips are lightweight and offer good conductivity.

- Less commonly used compared to GI and copper

- Preferred in some specific applications due to low weight

Earthing Strip Size Chart (Common Sizes in India)

| Size (Width x Thickness) | Typical Usage |

| 25 mm x 3 mm | Small panels, residential earthing |

| 25 mm x 6 mm | Standard earthing for homes and offices |

| 50 mm x 6 mm | Industrial earthing, transformers |

| 75 mm x 10 mm | Large electrical installations, substations |

(Note: Sizes can be customized by your Earthing Strip Manufacturer in India based on your project needs.)

Advantages of Using Earthing Strips

Let’s look at why earthing strips are preferred over other earthing methods:

- High Conductivity

They provide low-resistance paths for fault current. - Durability

Galvanized or copper strips last for many years with minimal maintenance. - Easy Installation

Flat strips are easy to connect, bend, and install at the site. - Cost-effective

Especially GI strips, which are affordable for all types of projects. - Versatile Applications

Suitable for homes, commercial buildings, industries, and plants.

Applications of Earthing Strips

Earthing strips are used in:

- Electrical panels and distribution boards

- Transformers and substations

- Solar power plants for grounding structures and inverters

- Oil refineries and chemical industries

- Telecommunication towers and equipment grounding

- Large buildings for lightning protection systems

How to Choose the Right Earthing Strip Manufacturer in India

Selecting a trusted Earthing Strip Manufacturer in India is important to ensure safety and quality. Here’s what you should check:

1. Quality Standards

Ensure the manufacturer supplies products as per IS standards (Indian Standards) with proper material test certificates.

2. Type of Materials Used

Check if they provide:

- Hot-dip galvanized strips for better rust resistance

- Pure copper strips with tested purity levels

- Customized sizes for specific projects

3. Experience and Reputation

Always choose a manufacturer with:

- Good market reputation

- Experience in supplying to major industries and contractors

- Positive client feedback

4. Delivery and Stock Availability

Time is construction money. Choose a manufacturer who:

- Maintains ready stock in common sizes

- Offers quick delivery across India

5. Competitive Pricing

While quality is a priority, pricing is equally important for project budgeting. Compare rates but never compromise on material quality.

Why Shobha Globs is a Trusted Earthing Strip Manufacturer in India

At Shobha Globs, we manufacture and supply high-quality earthing strips across India with:

- IS-standard compliance

- Hot-dip galvanized GI strips for longer life

- 99.9% pure copper strips for high conductivity

- Competitive pricing and ready stock

- Fast delivery to your project location

- Custom sizes available on order

We serve industries like electrical contractors, solar EPC companies, refineries, factories, and infrastructure developers.

Latest Trends in Earthing Strip Manufacturing

The earthing strip market in India is growing due to rising industrial and solar projects. Here are some trends:

- Use of PUF-coated earthing strips in coastal areas for extra corrosion protection

- Increasing demand for copper earthing strips in the oil & gas sectors

- Adoption of IS standards and BIS certifications by top manufacturers for government projects

- Rise in exports of GI strips to neighboring countries

Maintenance Tips for Earthing Strips

To ensure long life and safety:

- Inspect connections every 6-12 months for rust or loosening

- Ensure coating is intact; repaint GI strips if needed after years of use

- Check earth resistance values regularly, especially during monsoon

- Replace damaged strips immediately to avoid safety risks

Difference Between GI and Copper Earthing Strips

| Feature | GI Strip | Copper Strip |

| Conductivity | Good | Excellent |

| Cost | Affordable | Expensive |

| Corrosion resistance | Good (if galvanised properly) | Excellent |

| Weight | Heavy | Slightly heavier |

| Use case | Homes, commercial, and general industries | Oil refineries, chemical plants, power plants |

FAQs About Earthing Strips

Q1. Which earthing strip is better – GI or copper?

Both are good, but copper offers higher conductivity and durability. GI strips are more cost-effective for standard projects.

Q2. What is the life of a GI earthing strip?

If hot-dip galvanized and maintained properly, it can last 20-25 years.

Q3. Can I use aluminium strips for earthing?

Aluminium strips can be used in specific projects but are less common compared to GI and copper.

Q4. Do earthing strips require coating?

Yes, GI strips need galvanisation to prevent rust. Copper strips naturally resist corrosion.

Q5. Where can I buy earthing strips in bulk?

You can connect with Shobha Globs – Earthing Strip Manufacturer in India for bulk orders with competitive prices and quick delivery.

Final Thoughts

Choosing the right earthing strip ensures safety for people and equipment. Always buy from a trusted Earthing Strip Manufacturer in India who provides:

- Quality-tested materials

- IS-standard compliance

- Competitive pricing

- Timely delivery

This guarantees your project’s success without any safety risks.

Looking for the Best Earthing Strip Manufacturer in India?

At Shobha Globs, we provide durable and tested earthing strips to industries, EPC companies, and contractors across India. Contact us today to discuss your project needs and get a quick quotation.

Key Takeaways

- Earthing strips protect electrical systems and people from shocks.

- GI and copper strips are most common in India.

- Choose a manufacturer who offers quality, certification, and timely delivery.